URL: https://www.desy.de/news/news_search/index_eng.html

Breadcrumb Navigation

DESY News: Nanomaterials from a 3D X-ray perspective

News

News from the DESY research centre

Nanomaterials from a 3D X-ray perspective

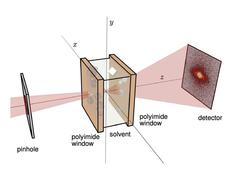

A new X-ray technique can be used to produce high resolution images of nanocrystals in real time as they are growing, something that has not been done before. To this end, a team from DESY and the University of Hamburg has created three-dimensional cross-sectional images of nanostructures from two-dimensional projections taken through a chemical reactor. The scientists achieved this using multi-slice X-ray ptychography, a technique in which an image is obtained computationally from the interference between coherent X-rays, that means rays that are oscillating in unison. The team is presenting its findings in the journal Scientific Reports.

In order to produce nanomaterials with carefully controlled properties, however, it is generally not enough to simply examine the end result of a manufacturing process. Ideally, scientists want to be able to observe every stage of the synthesis live, from the formation of the first crystals, a few nanometres across, until they assume their final form, allowing these processes to be individually controlled.

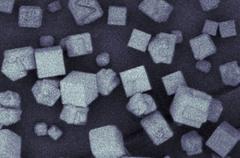

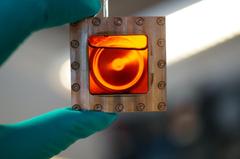

The scientists at DESY and the University of Hamburg have now taken a further step towards this goal with the help of multi-slice X-ray ptychography. “We wanted to observe nanocubes of copper oxide at the very moment they were growing inside a liquid,” explains lead author Maik Kahnt, from DESY, who now works at the MAX IV laboratory in Sweden. “We had to find out whether these nanocubes could actually be resolved and imaged through the walls of the container using modern X-ray-based imaging techniques,” adds co-author Lukas Grote, from the University of Hamburg. “And we have demonstrated that this is perfectly possible.”

One of the filled reaction chambers used in the X-ray experiment. In order to grow copper(I) oxide nanocubes inside it, the chamber must be heated to more than 150 degrees Celsius for at least one hour, and the temperature needs to be precisely controlled. Credit: DESY, Martin Seyrich

As a method, multi-slice ptychography therefore has the potential to track the formation of nanomaterials in real time. “To our knowledge, this is the first time this technique has been used in the context of a chemical reactor,” Grote reports. “Observing nanomaterials under real conditions using X-ray imaging nevertheless poses a number of technical challenges, because they are produced in a liquid medium at high temperatures and under high pressure.”

However, those involved in the collaboration between the Center for Hybrid Nanostructures (CHyN) at the University of Hamburg and DESY are confident that this will be possible in the future. There is also a huge technological significance to being able to observe the inside of chemical reactors almost in 3D, as Dorota Koziej, the CHyN group leader, emphasises: “Our ultimate goal is the controlled production of customised nanomaterials, for example for use as catalysts to produce green energy, or as inexpensive sensors for airborne pollutants.”

Schematic diagram of the experimental set-up: The X-ray beam (red) is focused on the chamber (reactor), passing through the entry and the exit windows and the heated liquid between them before striking the detector. Light scattered by the copper cubes on the inside of the windows creates interference patterns on the detector. These can be used to calculate high-resolution images of the copper cubes. Credit: MAX IV, Maik Kahnt

Reference:

Multi-slice ptychography enables high-resolution measurements in extended chemical reactors; Maik Kahnt, Lukas Grote, Dennis Brückner, Martin Seyrich, Felix Wittwer, Dorota Koziej und Christian G. Schroer; Scientific Reports, 2021; DOI: 10.1038/s41598-020-80926-6